How does stainless steel 304 transmission chain ensure efficient transmission?

Release Time : 2025-02-20

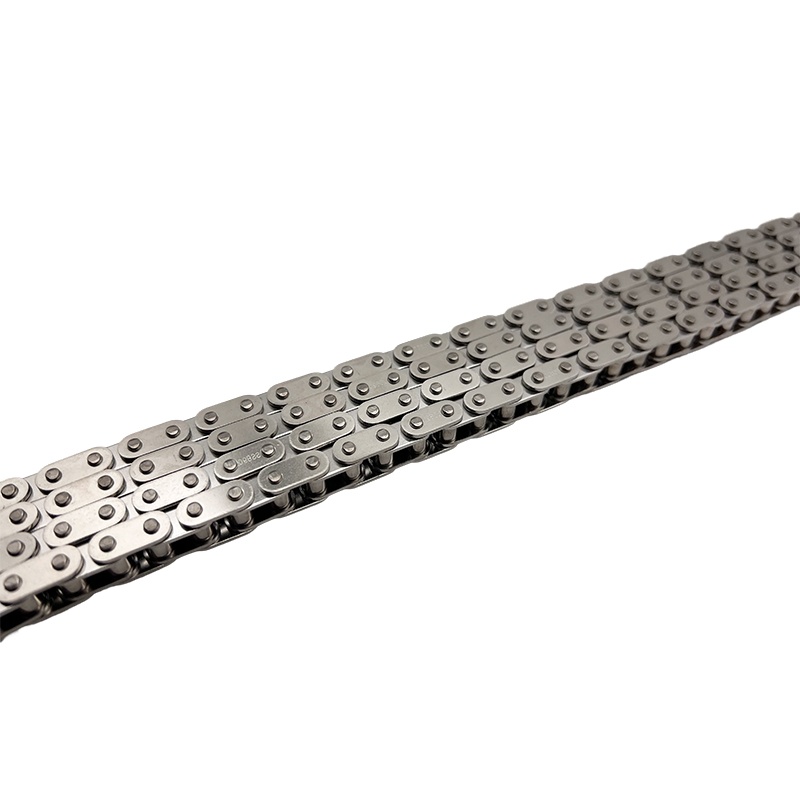

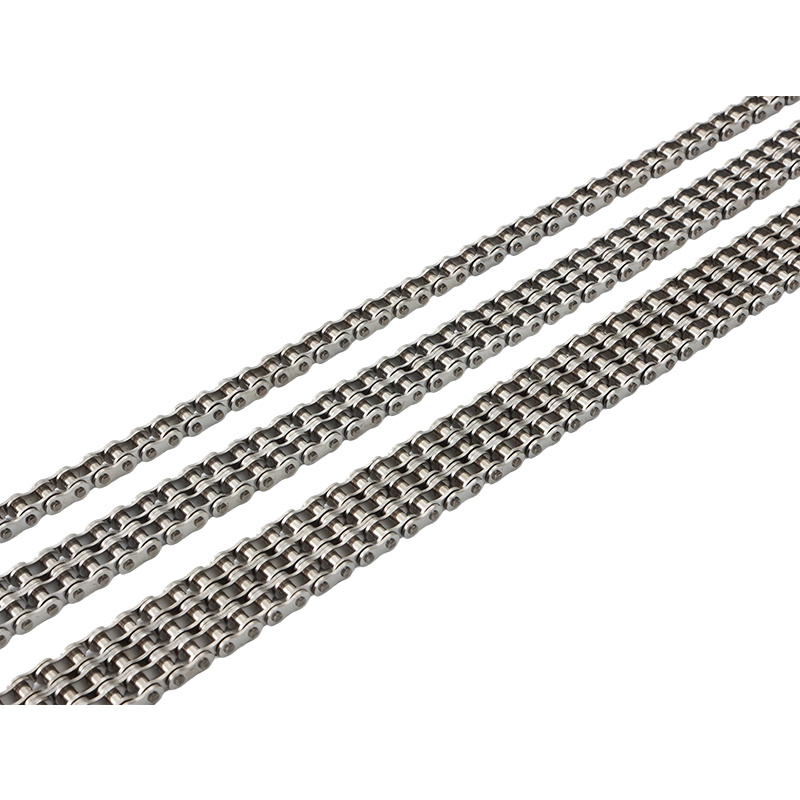

As an important mechanical transmission component, stainless steel 304 transmission chain has been widely used in the fields of industrial automation and mechanical transmission due to its high strength, corrosion resistance and high temperature resistance.

1. Material selection

Stainless steel 304 itself has good corrosion resistance, high temperature resistance and high strength, and is suitable for manufacturing transmission chains. However, in order to ensure the efficient transmission of the transmission chain, the uniformity, purity and microstructure of the material also need to be considered. High-quality 304 stainless steel can reduce wear and corrosion during the transmission process, thereby extending the service life of the transmission chain and improving the transmission efficiency.

2. Manufacturing process

Precise processing and heat treatment: Through precise processing and heat treatment processes, the hardness and wear resistance of the stainless steel 304 transmission chain can be improved while maintaining its good toughness and ductility. This helps to reduce energy loss and friction wear during the transmission process and improve transmission efficiency.

Fine surface treatment: Fine treatment of the surface of the transmission chain, such as polishing or sandblasting, can reduce the surface roughness and reduce the friction coefficient, thereby improving transmission efficiency.

3. Structural design

Reasonable structural design is essential to ensure efficient transmission of the transmission chain. This includes the shape, size and connection method of the chain links. By optimizing the structural design, the resistance and energy loss in the transmission process can be reduced and the transmission efficiency can be improved.

4. Lubrication and maintenance

Proper lubrication: The use of appropriate lubricants can reduce the friction and wear between the transmission chain and the sprocket, thereby reducing energy loss and improving transmission efficiency. At the same time, lubricants can also play a cooling and cleaning role, extending the service life of the transmission chain.

Regular maintenance: Regular inspection and maintenance of the transmission chain is also the key to ensure its efficient transmission. This includes checking the wear of the chain links, tightening the connecting bolts of the chain links, and replacing damaged chain links. Through regular maintenance, problems can be discovered and solved in time to avoid downtime of the transmission chain due to failure.

In summary, in order to ensure the efficient transmission of the stainless steel 304 transmission chain, it is necessary to comprehensively consider and optimize the material selection, manufacturing process, structural design, lubrication and maintenance, installation and commissioning, etc. Through the implementation of these measures, the transmission efficiency and service life of the transmission chain can be significantly improved, providing strong support for the development of industrial automation and mechanical transmission fields.

1. Material selection

Stainless steel 304 itself has good corrosion resistance, high temperature resistance and high strength, and is suitable for manufacturing transmission chains. However, in order to ensure the efficient transmission of the transmission chain, the uniformity, purity and microstructure of the material also need to be considered. High-quality 304 stainless steel can reduce wear and corrosion during the transmission process, thereby extending the service life of the transmission chain and improving the transmission efficiency.

2. Manufacturing process

Precise processing and heat treatment: Through precise processing and heat treatment processes, the hardness and wear resistance of the stainless steel 304 transmission chain can be improved while maintaining its good toughness and ductility. This helps to reduce energy loss and friction wear during the transmission process and improve transmission efficiency.

Fine surface treatment: Fine treatment of the surface of the transmission chain, such as polishing or sandblasting, can reduce the surface roughness and reduce the friction coefficient, thereby improving transmission efficiency.

3. Structural design

Reasonable structural design is essential to ensure efficient transmission of the transmission chain. This includes the shape, size and connection method of the chain links. By optimizing the structural design, the resistance and energy loss in the transmission process can be reduced and the transmission efficiency can be improved.

4. Lubrication and maintenance

Proper lubrication: The use of appropriate lubricants can reduce the friction and wear between the transmission chain and the sprocket, thereby reducing energy loss and improving transmission efficiency. At the same time, lubricants can also play a cooling and cleaning role, extending the service life of the transmission chain.

Regular maintenance: Regular inspection and maintenance of the transmission chain is also the key to ensure its efficient transmission. This includes checking the wear of the chain links, tightening the connecting bolts of the chain links, and replacing damaged chain links. Through regular maintenance, problems can be discovered and solved in time to avoid downtime of the transmission chain due to failure.

In summary, in order to ensure the efficient transmission of the stainless steel 304 transmission chain, it is necessary to comprehensively consider and optimize the material selection, manufacturing process, structural design, lubrication and maintenance, installation and commissioning, etc. Through the implementation of these measures, the transmission efficiency and service life of the transmission chain can be significantly improved, providing strong support for the development of industrial automation and mechanical transmission fields.