Deciphering why stainless steel 304 transmission chain is the ideal choice for transmission system

Release Time : 2025-03-21

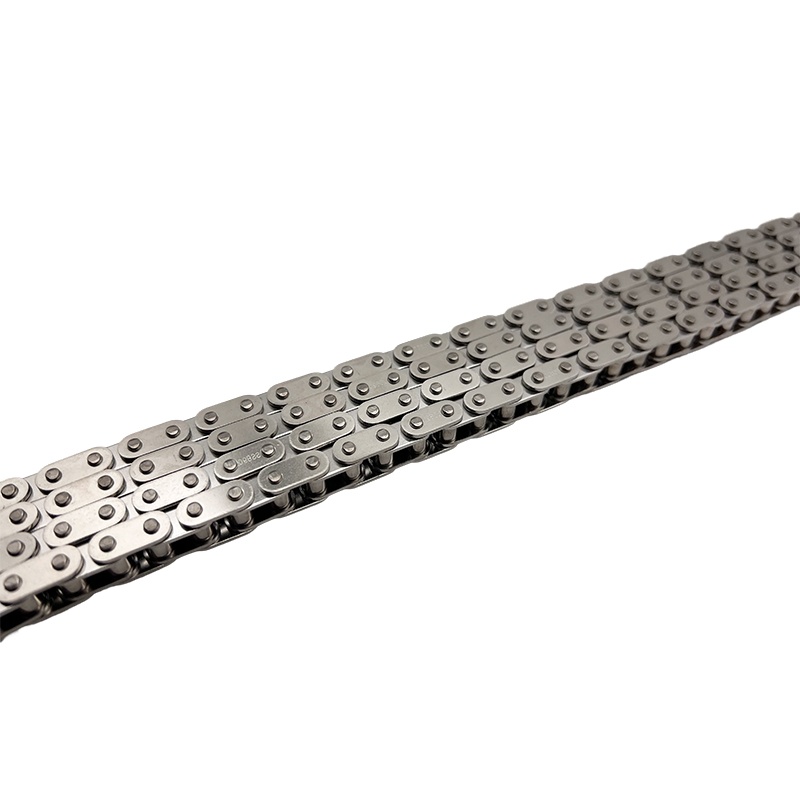

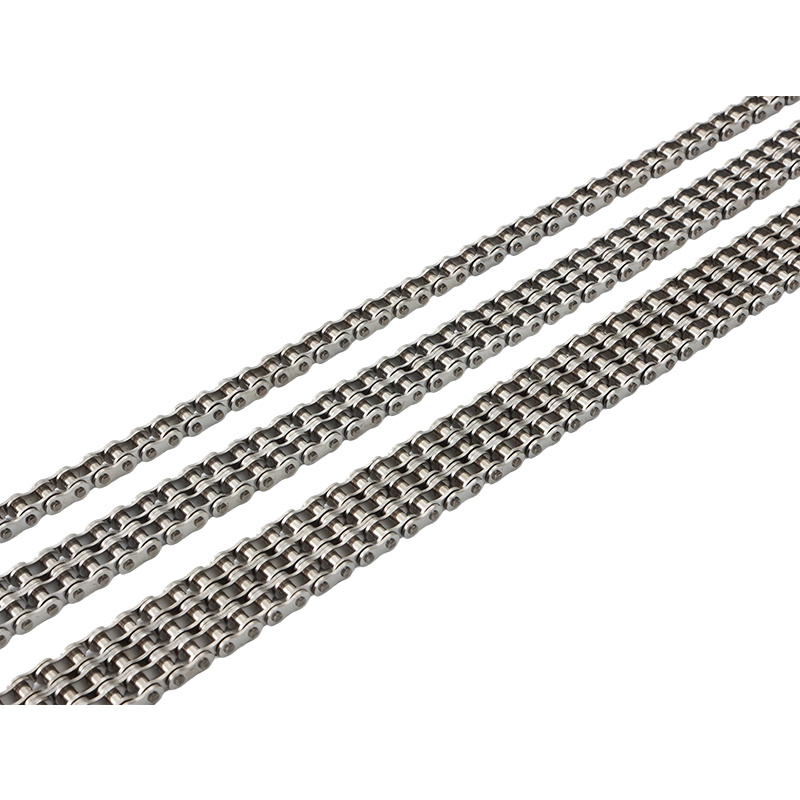

As a key component in the transmission system, stainless steel 304 transmission chain has been widely used in many industrial fields due to its unique material characteristics and excellent performance.

1. Material advantages

Stainless steel 304 transmission chain is mainly made of 304 stainless steel, which has excellent corrosion resistance and high strength. 304 stainless steel contains 18% chromium and 8% nickel, which can effectively resist common corrosive media such as acids, alkalis, and salts, and is suitable for humid and corrosive industrial environments. At the same time, its high strength characteristics make the chain less likely to break or deform when bearing heavy loads and high-speed transmission, thereby ensuring the stability and reliability of the transmission system.

2. Excellent performance

Strong wear resistance: The stainless steel 304 transmission chain has been treated with special processes, with high surface hardness and strong wear resistance, and can maintain transmission efficiency for a long time.

Strong load-bearing capacity: The chain can withstand large tension and pressure, is suitable for heavy-duty transmission systems, and meets various high-strength transmission requirements.

High temperature resistance: In high temperature environment, stainless steel 304 chain can still maintain excellent mechanical properties and appearance stability, ensuring the continuous and stable operation of the transmission system.

3. Wide application

The application field of stainless steel 304 transmission chain is very wide, including but not limited to:

Food processing: In the food processing industry, stainless steel chains are widely used in conveyor belts, mixers and other equipment due to their corrosion resistance and easy cleaning to ensure food safety and hygiene.

Automation equipment: In the automated production line, stainless steel chains are used as transmission components to ensure the stable operation and efficient production of equipment.

Chemical industry: In the chemical industry, stainless steel chains can resist the erosion of chemical substances and are suitable for the transportation and mixing of various corrosive media.

Machinery manufacturing: In the field of machinery manufacturing, stainless steel chains are used in various transmission systems, such as cranes, conveyors, etc., to carry heavy loads and transmit power.

4. Easy maintenance and maintenance

The structure of stainless steel 304 transmission chain is relatively simple, easy to disassemble and replace, and reduces maintenance costs. In order to ensure the long-term stable operation of the chain, it is necessary to perform regular maintenance and care, including checking the wear of the chain, whether the fasteners are loose, etc., to promptly detect and deal with problems; regularly clean the dirt and grease on the surface of the chain, and apply an appropriate amount of lubricant to reduce friction and wear; ensure that the chain works within the rated load range to avoid overload and chain damage.

In summary, stainless steel 304 transmission chain has become an ideal choice for transmission systems due to its material advantages, excellent performance, wide application fields, and easy maintenance and care.

1. Material advantages

Stainless steel 304 transmission chain is mainly made of 304 stainless steel, which has excellent corrosion resistance and high strength. 304 stainless steel contains 18% chromium and 8% nickel, which can effectively resist common corrosive media such as acids, alkalis, and salts, and is suitable for humid and corrosive industrial environments. At the same time, its high strength characteristics make the chain less likely to break or deform when bearing heavy loads and high-speed transmission, thereby ensuring the stability and reliability of the transmission system.

2. Excellent performance

Strong wear resistance: The stainless steel 304 transmission chain has been treated with special processes, with high surface hardness and strong wear resistance, and can maintain transmission efficiency for a long time.

Strong load-bearing capacity: The chain can withstand large tension and pressure, is suitable for heavy-duty transmission systems, and meets various high-strength transmission requirements.

High temperature resistance: In high temperature environment, stainless steel 304 chain can still maintain excellent mechanical properties and appearance stability, ensuring the continuous and stable operation of the transmission system.

3. Wide application

The application field of stainless steel 304 transmission chain is very wide, including but not limited to:

Food processing: In the food processing industry, stainless steel chains are widely used in conveyor belts, mixers and other equipment due to their corrosion resistance and easy cleaning to ensure food safety and hygiene.

Automation equipment: In the automated production line, stainless steel chains are used as transmission components to ensure the stable operation and efficient production of equipment.

Chemical industry: In the chemical industry, stainless steel chains can resist the erosion of chemical substances and are suitable for the transportation and mixing of various corrosive media.

Machinery manufacturing: In the field of machinery manufacturing, stainless steel chains are used in various transmission systems, such as cranes, conveyors, etc., to carry heavy loads and transmit power.

4. Easy maintenance and maintenance

The structure of stainless steel 304 transmission chain is relatively simple, easy to disassemble and replace, and reduces maintenance costs. In order to ensure the long-term stable operation of the chain, it is necessary to perform regular maintenance and care, including checking the wear of the chain, whether the fasteners are loose, etc., to promptly detect and deal with problems; regularly clean the dirt and grease on the surface of the chain, and apply an appropriate amount of lubricant to reduce friction and wear; ensure that the chain works within the rated load range to avoid overload and chain damage.

In summary, stainless steel 304 transmission chain has become an ideal choice for transmission systems due to its material advantages, excellent performance, wide application fields, and easy maintenance and care.