How to improve the fatigue resistance of stainless steel 304 transmission chain by improving material processing?

Release Time : 2025-04-05

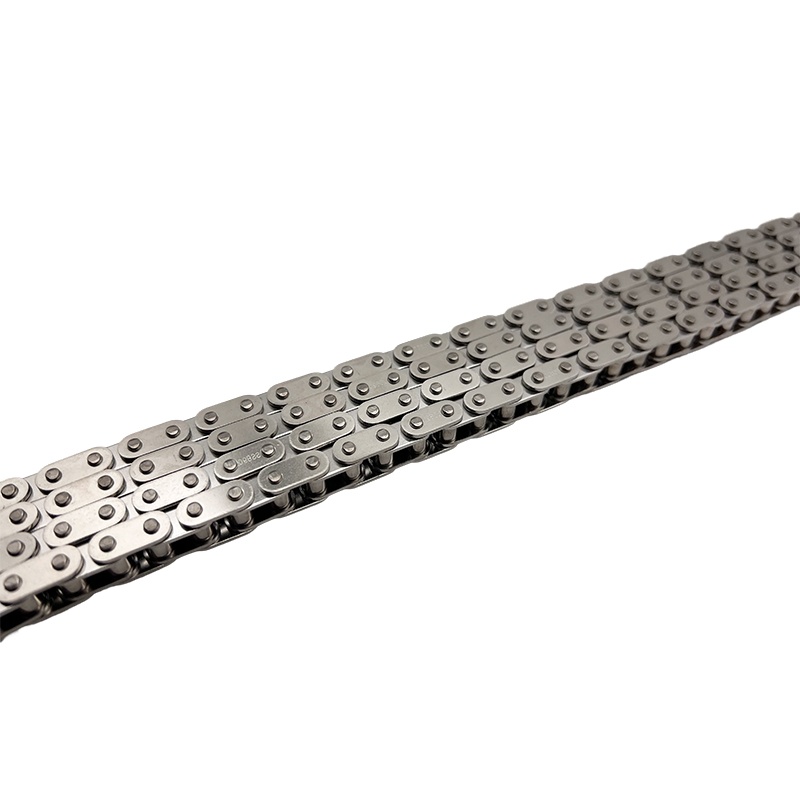

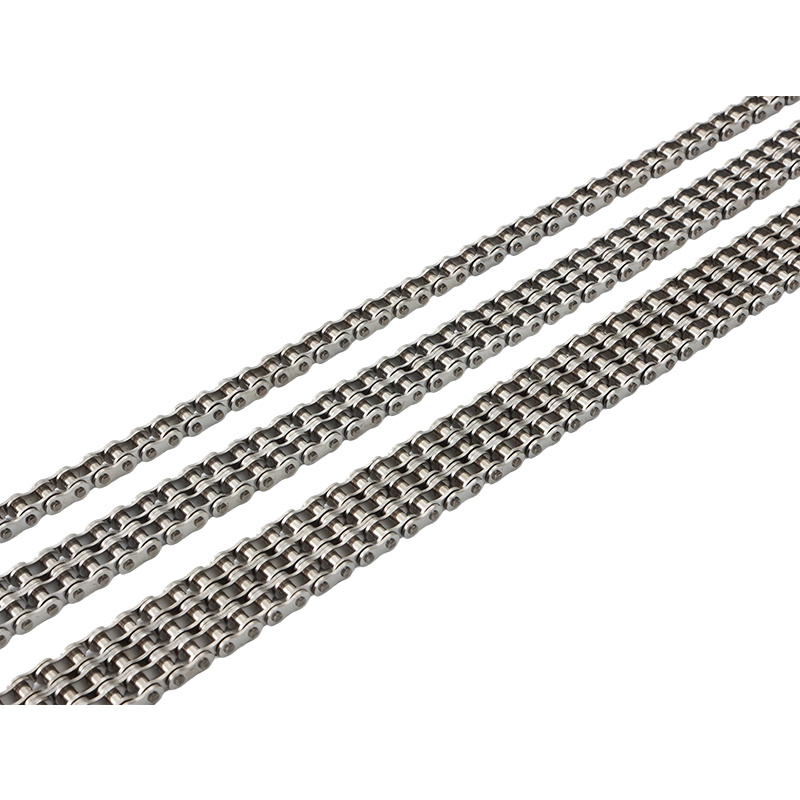

Improving the fatigue resistance of stainless steel 304 transmission chain is essential to ensure its reliability and long life in various industrial applications. The fatigue resistance of the chain can be enhanced in many ways by improving the material processing process, which not only involves selecting the right raw materials, but also requires precise control of every step in the manufacturing process. In-depth exploration of this topic can reveal how to optimize the quality and performance of stainless steel 304 transmission chain with modern technology.

First of all, in terms of the selection of raw materials, although 304 stainless steel itself has good corrosion resistance and certain strength, in order to further improve its fatigue resistance, it is possible to consider using higher purity raw materials or adding trace alloying elements to adjust the microstructure of the material. For example, by increasing the nickel content or adding a small amount of elements such as molybdenum, the toughness and fatigue crack growth resistance of the material can be significantly improved without significantly affecting the cost. In addition, strict screening of raw material suppliers to ensure that each batch of steel meets strict chemical composition standards is the basis for ensuring the quality of the final product.

Next, heat treatment plays a vital role in improving the fatigue resistance of stainless steel 304 transmission chain. Traditional solution annealing can form a uniform austenite structure inside the material, thereby improving its comprehensive mechanical properties. However, for specific application scenarios, more advanced heat treatment methods such as graded quenching or cryogenic treatment may be required. These technologies can reduce residual stress and eliminate small defects while refining the grains, effectively preventing the initiation and development of fatigue cracks. It is worth noting that the precise control of temperature, time and cooling rate during heat treatment is particularly critical, and any deviation may lead to a decrease in material performance.

In addition to heat treatment, surface treatment is also one of the effective means to enhance the fatigue resistance of stainless steel 304 transmission chain. For example, shot peening technology can introduce a compressive stress layer on the surface of the chain. This preload helps to inhibit the formation of fatigue cracks and slow down the propagation rate of existing cracks. Similarly, surface modification technologies such as nitriding or carbonitriding can also significantly improve the surface hardness and wear resistance of the material, indirectly enhancing the overall fatigue resistance of the chain. However, when implementing these surface treatments, care should be taken to avoid the problem of excessive hardening leading to increased brittleness.

During the manufacturing process, the quality of welding has a direct impact on the fatigue resistance of the stainless steel 304 transmission chain. High-quality welding not only ensures the mechanical strength of the joint, but also minimizes the stress concentration in the welding area. To this end, professional welding techniques and filler materials suitable for stainless steel should be selected, and the operating procedures should be strictly followed. At the same time, non-destructive testing methods such as ultrasonic testing and X-ray flaw detection should be used to conduct a comprehensive inspection of the joints to promptly detect and repair potential defects to ensure the safety and reliability of each link.

Finally, considering the impact of the actual working environment on the stainless steel 304 transmission chain, the role of external factors must be fully considered in the design stage. For example, chains working in high humidity or salty environments, in addition to requiring themselves to have excellent corrosion resistance, should also take additional protective measures, such as coating anti-corrosion coatings or using sealing devices, to prevent moisture intrusion from causing internal corrosion and then fatigue damage. In addition, setting the working load range of the chain reasonably to avoid long-term operation under extreme load conditions can also help extend the service life.

In short, by carefully selecting raw materials, optimizing heat treatment and surface treatment processes, and strengthening quality management during the manufacturing process, the fatigue resistance of stainless steel 304 transmission chain can be greatly improved. This not only helps to meet the increasingly stringent industrial needs, but also provides a solid guarantee for promoting the development of related industries.

First of all, in terms of the selection of raw materials, although 304 stainless steel itself has good corrosion resistance and certain strength, in order to further improve its fatigue resistance, it is possible to consider using higher purity raw materials or adding trace alloying elements to adjust the microstructure of the material. For example, by increasing the nickel content or adding a small amount of elements such as molybdenum, the toughness and fatigue crack growth resistance of the material can be significantly improved without significantly affecting the cost. In addition, strict screening of raw material suppliers to ensure that each batch of steel meets strict chemical composition standards is the basis for ensuring the quality of the final product.

Next, heat treatment plays a vital role in improving the fatigue resistance of stainless steel 304 transmission chain. Traditional solution annealing can form a uniform austenite structure inside the material, thereby improving its comprehensive mechanical properties. However, for specific application scenarios, more advanced heat treatment methods such as graded quenching or cryogenic treatment may be required. These technologies can reduce residual stress and eliminate small defects while refining the grains, effectively preventing the initiation and development of fatigue cracks. It is worth noting that the precise control of temperature, time and cooling rate during heat treatment is particularly critical, and any deviation may lead to a decrease in material performance.

In addition to heat treatment, surface treatment is also one of the effective means to enhance the fatigue resistance of stainless steel 304 transmission chain. For example, shot peening technology can introduce a compressive stress layer on the surface of the chain. This preload helps to inhibit the formation of fatigue cracks and slow down the propagation rate of existing cracks. Similarly, surface modification technologies such as nitriding or carbonitriding can also significantly improve the surface hardness and wear resistance of the material, indirectly enhancing the overall fatigue resistance of the chain. However, when implementing these surface treatments, care should be taken to avoid the problem of excessive hardening leading to increased brittleness.

During the manufacturing process, the quality of welding has a direct impact on the fatigue resistance of the stainless steel 304 transmission chain. High-quality welding not only ensures the mechanical strength of the joint, but also minimizes the stress concentration in the welding area. To this end, professional welding techniques and filler materials suitable for stainless steel should be selected, and the operating procedures should be strictly followed. At the same time, non-destructive testing methods such as ultrasonic testing and X-ray flaw detection should be used to conduct a comprehensive inspection of the joints to promptly detect and repair potential defects to ensure the safety and reliability of each link.

Finally, considering the impact of the actual working environment on the stainless steel 304 transmission chain, the role of external factors must be fully considered in the design stage. For example, chains working in high humidity or salty environments, in addition to requiring themselves to have excellent corrosion resistance, should also take additional protective measures, such as coating anti-corrosion coatings or using sealing devices, to prevent moisture intrusion from causing internal corrosion and then fatigue damage. In addition, setting the working load range of the chain reasonably to avoid long-term operation under extreme load conditions can also help extend the service life.

In short, by carefully selecting raw materials, optimizing heat treatment and surface treatment processes, and strengthening quality management during the manufacturing process, the fatigue resistance of stainless steel 304 transmission chain can be greatly improved. This not only helps to meet the increasingly stringent industrial needs, but also provides a solid guarantee for promoting the development of related industries.