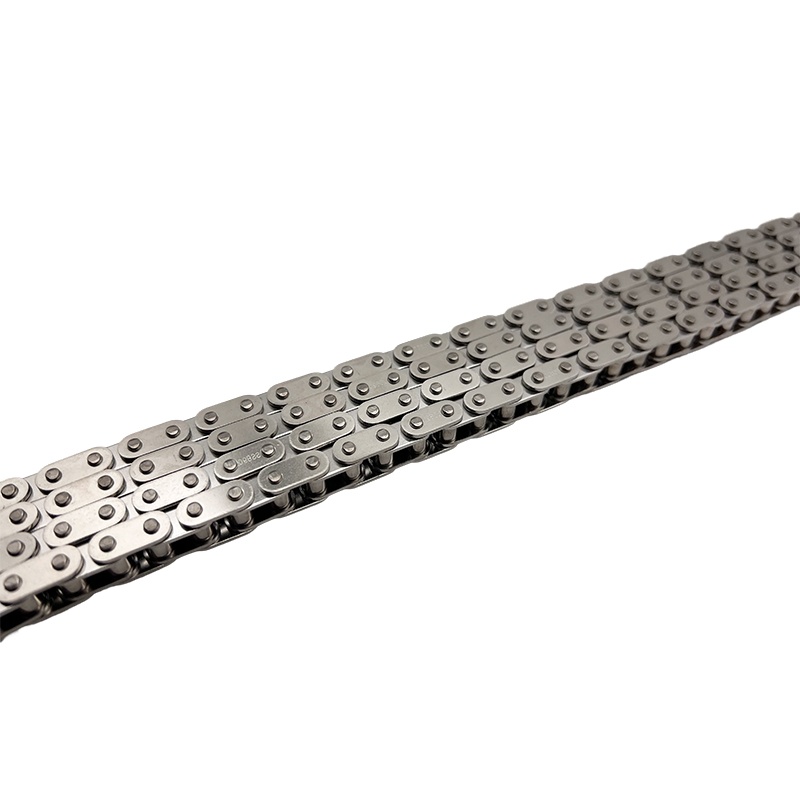

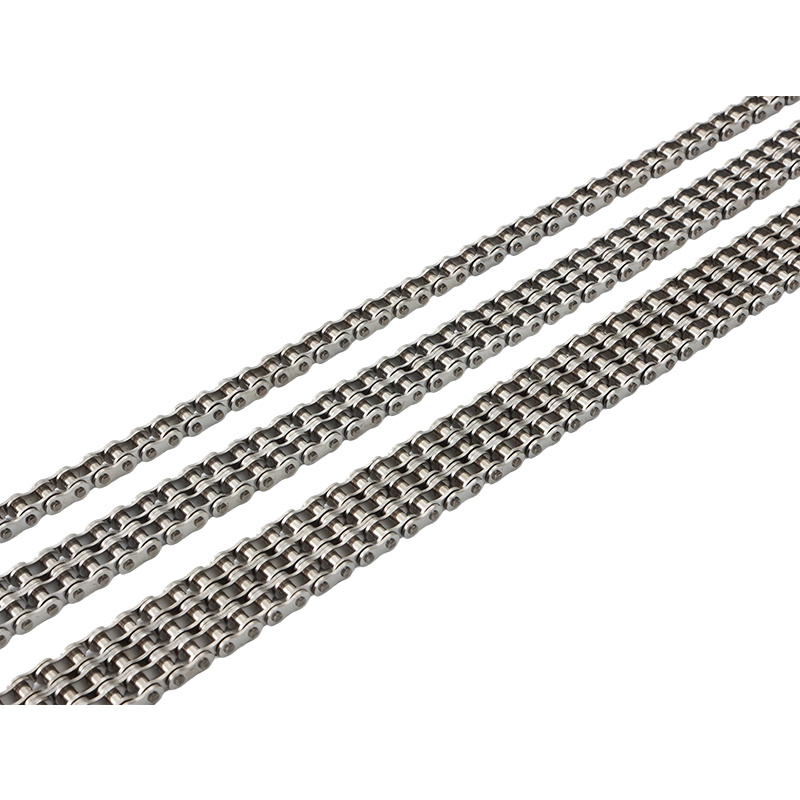

How to properly clean a stainless steel 304 transmission chain to avoid wear?

Release Time : 2025-04-17

Before cleaning the stainless steel 304 transmission chain, a comprehensive and detailed inspection and preparation must be done. First, ensure that the transmission chain is completely stopped, cut off the power supply of the equipment, set up obvious warning signs to prevent the equipment from accidentally starting during the cleaning process, so as to ensure the personal safety of the operator. Then, carefully observe the appearance of the transmission chain to check whether there are any abnormal conditions such as loose links, deformed chain plates, surface scratches, etc. At the same time, use professional tools to measure the degree of wear of the links and record relevant data to provide a basis for subsequent cleaning and maintenance. In addition, prepare the tools required for cleaning, such as soft brushes, clean rags, protective gloves, suitable detergents and lubricants, etc., to ensure the cleanliness of the tools and avoid secondary contamination of the transmission chain due to impurities carried by the tools themselves.

The choice of detergent has a direct impact on the cleaning effect and service life of the stainless steel 304 transmission chain. Since stainless steel 304 has good corrosion resistance, but is not completely impervious to chemical attack, strong acidic or alkaline cleaners should be avoided, as they may react chemically with the stainless steel surface, destroy its passivation film, reduce corrosion resistance, and accelerate wear. You can choose a neutral cleaner designed specifically for stainless steel. This type of cleaner can effectively dissolve and remove dirt such as oil, dust, and metal debris on the surface of the transmission chain without damaging the stainless steel surface. In addition, organic solvents such as alcohol and kerosene can also be used. They have a significant cleaning effect on oil and stubborn stains, and are volatile. After cleaning, there will not be too much liquid left, which reduces the adverse effects of moisture on the transmission chain.

When cleaning the stainless steel 304 transmission chain, a gentle and effective method should be used to avoid increased wear due to improper operation. First, use a soft brush to gently brush away the dust and larger particles of impurities attached to the surface of the transmission chain. When brushing, follow the direction of the chain link, avoid brushing horizontally or in reverse, and prevent the bristles from hooking the chain link and causing damage. For oil stains and stubborn stains, you can evenly apply the detergent on the surface of the transmission chain and let it work for a few minutes. After the oil stains are fully dissolved, wipe it with a clean rag or use a soft brush to gently scrub it. During the cleaning process, pay special attention to the gaps in the transmission chain, the joints of the chain links, and other parts that are easy to hide dirt and ensure thorough cleaning. At the same time, avoid using too hard tools, such as wire brushes, etc., so as not to scratch the surface of the stainless steel and damage its protective layer.

After wiping or scrubbing with the detergent, the transmission chain needs to be thoroughly rinsed to remove residual detergent and dirt. Use clean water and low-pressure water flow to slowly rinse from one end of the transmission chain to the other end, ensuring that the water flow can fully rinse all parts of the chain link. During the rinsing process, carefully check whether there is any detergent residue, especially in the gaps and dead corners. After rinsing, dry it immediately, because residual moisture may cause stainless steel to rust, which will affect the performance and life of the transmission chain. You can use a clean dry rag to wipe the moisture off the surface of the transmission chain, or you can use compressed air to blow dry to completely remove the moisture from all parts of the transmission chain. Make sure that the transmission chain enters the subsequent maintenance link in a completely dry state.

After cleaning and drying, the stainless steel 304 transmission chain needs to be properly lubricated, which is a key step to reduce friction and wear. It is very important to choose the right lubricant. You should choose a lubricant with good anti-oxidation, anti-wear and anti-rust properties, and its viscosity should meet the working requirements of the transmission chain. When applying the lubricant, make sure to evenly cover all the links of the transmission chain, the contact parts between the chain and the sprocket, etc. You can use dripping, spraying or dipping to accurately apply the lubricant to the parts that need lubrication. After applying, let the transmission chain run slowly for a while so that the lubricant can fully penetrate into the inside of the chain links and each friction surface to form an effective lubricating film, thereby reducing the friction resistance during the transmission process and reducing the degree of wear.

In order to continuously maintain the good performance of the stainless steel 304 transmission chain and reduce wear, it is essential to formulate a regular cleaning and maintenance plan. According to the frequency of use, working environment and load of the transmission chain, the cleaning and maintenance cycle should be reasonably determined. For example, in a harsh working environment with heavy dust and oil pollution, the cleaning cycle should be appropriately shortened; while in a relatively clean environment with light load, the cleaning cycle can be appropriately extended. After each cleaning and maintenance, detailed records should be kept, including cleaning time, cleaning methods, types of cleaning agents and lubricants used, problems found and treatment measures, so as to track and analyze the operation status of the transmission chain, timely discover potential problems and take corresponding solutions.

The professional level and safety awareness of operators play an important role in correctly cleaning the stainless steel 304 transmission chain and avoiding wear. Enterprises should regularly organize professional training for operators to familiarize them with the structure, working principle, cleaning and maintenance methods and relevant safety operating procedures of the transmission chain. The training content should not only include theoretical knowledge, but also practical operation demonstrations and exercises to ensure that operators can master cleaning and maintenance skills. At the same time, it is necessary to continuously strengthen the safety awareness of operators, make them fully aware of the potential risks in cleaning and maintenance work, strictly abide by safety regulations, and put an end to illegal operations, so as to ensure the smooth progress of cleaning and maintenance work and extend the service life of the stainless steel 304 transmission chain.